DTM 3650™ Digital Terrain Mapping

Give your operators precise guidance, so they can dig exactly where it’s needed.

Reliable and accurate Lidar technology reduces dig to plan errors before moving your dragline.

How Digital Terrain Mapping Works

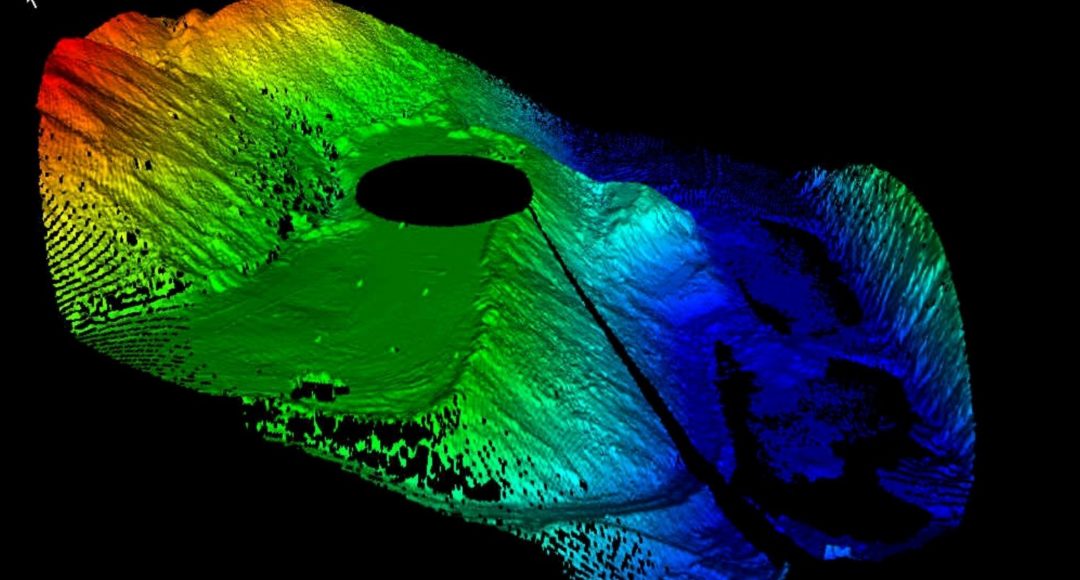

DTM 3650 uses Lidar and a GPS receiver on the dragline boom to scan the ground and accurately pinpoint the machine’s location.

Lidar is a remote sensing technology that uses light to detect shapes and objects from a distance. It produces highly detailed images even in low lighting, making it well suited to mining applications.

Product Features

OEM-Agnostic

DTM 3650 works with any dragline make and model, so your entire fleet can benefit from digital terrain mapping.

Real-Time 3D Map

Operators will always know where to dig with a continuously updated, adaptive 3D map of the surrounding terrain.

99% Up time

Mining operations never stop and neither does DTM 3650.

More Productive Digging

Save time and fuel by directing operators to position machines with confidence, avoiding unnecessary dragline repositioning.

Minimize Rehandle

Some level of rehandle (when overburden is handled more than once) is inevitable, but proper planning can minimize it, increasing productivity and profits.

A Safer Pit

By relying on DTM 3650’s accurate digital terrain mapping, you can minimize surveyors in the pit, keeping them out of harm’s way.

Our door is always open

Get in touch to start the conversation

We thrive on building collaborative partnerships with the world’s best miners.

If that sounds like you, we’d love to talk.

Contact Us

Fill out the form to get the ball rolling.